How to Choose the Right Steel for Your Storm Shelter

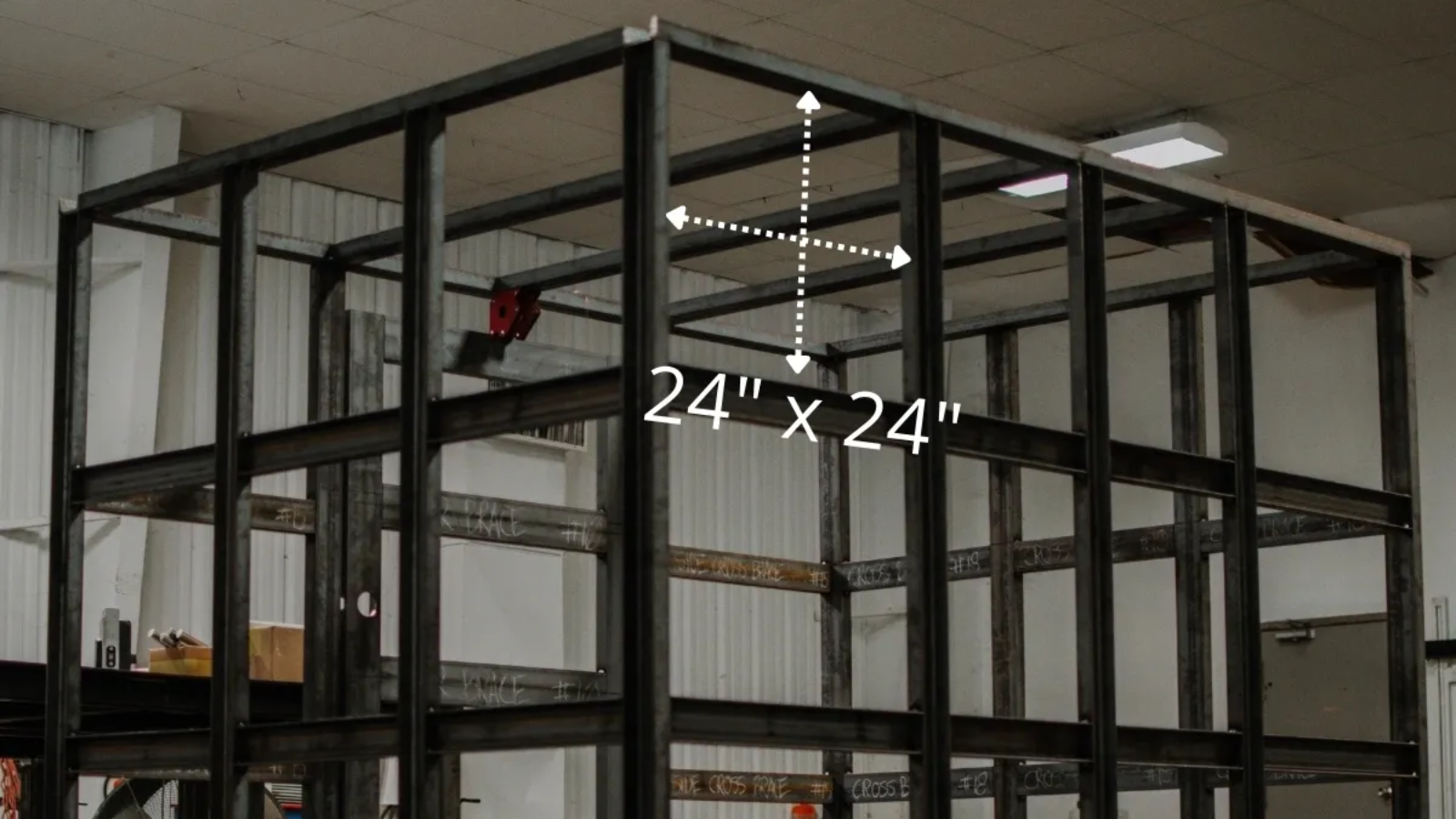

You’ve decided to build a storm shelter on your property, and there are two ways you can go about it—you can build it yourself, or you can hire a blacksmith to create one for you out of steel. The latter option has several advantages, not the least of which being that you don’t have to lift thousands of pounds of steel into place! Before you decide on building or buying your shelter, though, it’s important to know what kind of steel works best.

The Physical Properties of Steel

Metals can be broken down into two categories: ferrous and nonferrous. Nonferrous metals, such as aluminum, copper, gold, and lead are generally soft metals that can be pliable at room temperature. Ferrous metals include everything from stainless steel to simple iron. These tend to be harder than nonferrous metals and more durable. When it comes to building a storm shelter, you’ll want a material that’s both strong and resistant to rusting or corrosion. Our material of choice for the best strength, cost, and purpose is carbon steel coated with the best primer and paint. Here is more on the process.

The Manufacturing Processes That Form Steel

When considering a storm shelter, most people look at durability and price. However, another factor that could determine which shelter is right for you is what type of steel was used to make it. There are a number of different manufacturing processes that form steel into different shapes and sizes, each with their own benefits and drawbacks. Knowing more about these processes will help you make an informed decision on what type of steel will suit your needs best. Let’s take a closer look at three popular methods: hot rolled, cold rolled, and forging.

Forging steel involves heating a solid piece of metal until it’s malleable enough to pound, bend, and shape. Forged steel can be created through two distinct methods: drop-forging or die-forging. Both techniques generate high temperatures in order to soften and reshape metals but each generates those temperatures differently. Drop forging requires less heat than die forging because it relies on gravity to drive down heavy steel hammers onto heated bars. Die forging, on the other hand, uses hydraulic pressure to press heated pieces into molds with dies that have been shaped exactly like what you want your finished product to look like.

Cold rolled steel is a type of alloyed steel that has been formed by rolling sheets of hot rolled steel at cold temperatures between -200°F and -400°F. This process results in a material with high strength, moderate ductility, and good toughness. Because it’s formed through heat-treating after it’s cooled down, it can be produced in thinner gauges than other types of steel—which means less material used overall.

Hot rolled steel is made from an ingot that’s heated up to between 2,000°F and 3,000°F before being drawn through rollers while still red-hot. The rolling process compresses and lengthens steel in order to produce large sheets of flat material with a consistent thickness. The end result is a product that has good strength, ductility, hardness, and toughness—making it a popular choice for manufacturing many different types of products.

Choosing Your Material

When it comes to building a storm shelter, you need one that’s sturdy and durable. That said, steel is one of your best bets as it has excellent tensile strength and can withstand strong winds; however, there are different kinds of steel and each one requires a different manufacturing process. This makes choosing a material somewhat complicated, so here’s a rundown on what you should consider: Hot Rolled Steel: Also known as HR or HRS, hot rolled steel comes in flat sheets or coils. It’s an economical option but doesn’t have great ductility, meaning it tends to be weaker than other types of steel. Cold Rolled Steel: Cold rolled steel (CRS) is produced by passing sheet metal through rollers at high speeds. CRS offers good ductility and resistance to abrasion but isn’t as strong as other options like galvanized or stainless steel.

You could also opt for another type of steel such as galvanized or stainless steel. While these two options tend to be more expensive than HR or CRS, they offer better corrosion resistance which means they could last longer when exposed to harsh weather conditions.

What Are Other Factors In Selecting The Right Storm Shelter?

Once you’ve decided upon a 100% steel residential storm shelter or commercial storm shelter, you’ll want to ensure that the storm shelter meets these codes and standards:

ICC 500 (2020) – latest building code

FEMA P361

FEMA P360

For more information visit RemainSafe at www.RemainSafe.com. Or call (256) 506-9449 for more information. You can also email sales@remainsafe.com.

Andy Smith

Founding CEO of BlackSmith Ventures